Knurled holders for machine tools

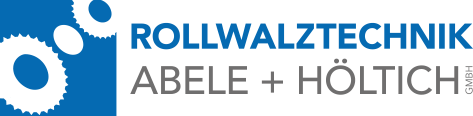

Knurling-head

This three wheeled form knurling tool performs knurlings on small diameter workpieces. Three knurl jaws are moved by a synchronizing ring that allows an easy adjustment to the workpiece´s diameter. The coupling between the shank and the head has an auto adjusting system to compensate differences between the turret and the chuck of the machine.

To apply for: Face-knurling for axial feedAxial: AA, GE 30°, GE 45°

Machinse types: Conventional, CNC, multi-spindle, sliding head and Swiss type lathes.

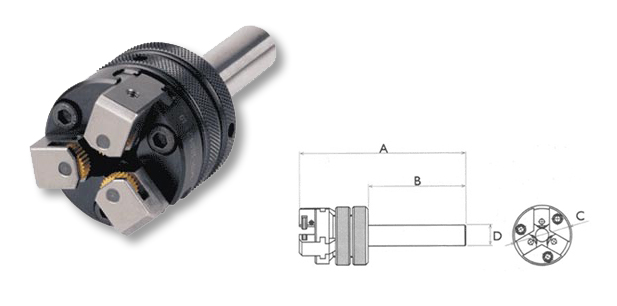

Knurl holder “Conical”

This form knurling holder enables conical knurlings on right- and left-handed lathes especially in DIN-72783. The modular system allows the use of several different shanks keeping the same components. A threaded spindle enables easy adjustment to the workpiece´s diameter and an auto-centering system compensates a possible disalignment between the turret and the machine axis.

Mechanical stress is stood by the holder and not transmitted to the bearings of the machine. Even the bending risk in the workpiece is eliminated as each knurl’s pressure compensates one with each other.

Axial: KAA, KBL 30°, KGE 45°

Machines types: Manual, automatic, Swiss type, multi-spindle and CNC Lathes

Internal holder “Bore”

Internal Holders are intended to be used boring bar style (off center). Each of them has flats on diameter of shank to allow mounting in tool post. Maximum depth that can be knurled will vary with toughness of material to be knurled.

To apply for: Internal form knurling holder for boring bar style (off center) for axial and radial feeding.Radila feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Manual, automatic, Swiss type, sliding-head, multi-spindle and CNC Lathes

Shank conical knurl dies with TIN coating

knurling holder “Fixed” and “Adjustable”

The fixed and also the adjustable face-knurling holder are available in a standard or heavy duty version. The buildup of the fixed and the adjustable holder is the same, the adjustable holder allows to double the knurl up to a diameter of 64 mm. When knurling on these larger diameter the tip of the die is not on the center of the part, but if the knurl “band” on the part is narrow an acceptable impression can be made. In general if the rate of pitch change on the part is within 10 % of the rate of pitch change on the die a good straight knurl will be made.

To apply for: Face form knurling tool for radial feeding.Axial: AA

Machines types: conventional, multi-spindle and CNC lathes.

Cut-knurl holder “RGE-VDI” with VDI-Shaft according to DIN 69880

Approved cut knurling holder with a tilting and scaled head for a better knurl alignment to the workpiece diameter and easy adjustment of the parallelity. Possibility to work on right- and left-handed lathes just turning over the head. The modular system allows the use of several different shanks.

To apply for: Cut knurling tool only for axial feed. The beginning of a knurling in the middle of the workpiece requires a puncture. Knurlings up to a shoulder are not possible.Axial: RGE 30°, RGE 45°, RGE 60°

Machines types: CNC lathes equipped with a DIN 69880 turret.

Knurl holder “RGE”

Approved form knurling holder

To apply for: Form knurling tool for axialbump knurling and axial feeding to produce a diamond knurlRadial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machine types: Swiss type, multi-spindle, conventional, sliding-B head and CNC lathes.

Cut-knurl holder “RAA”

Robust and approved cut knurling holder with easy adjustment of the parallelity and scaled head for the adjustment of the angle. Possibility to work on right- and left-handed lathes just turning over the head. The modular system allows the use of several different shanks.

To apply for: Cut knurling tool only for axial feeding. The beginning of a knurling in the middle of the workpiece requires a puncture. Knurlings up to a shoulder are not possible.Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Multi-spindle, conventional, sliding-head and CNC lathes.

Knurl holder “Swiveling”

Approved self centering form knurling holder with two wheels for small and medium sized lathes. Stress is absorbed by the tool and not transmitted to the bearings of the machine. It also eliminates bending risks on the workpiece as each knurl’s pressure compensates one with each other.

For apply to: Form knurling tool for axialaxial and radial feeding.Radial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

Knurling holder "Shoulder-Heavy-Double"

Approved heavy-duty holder with two wheels for left- and right-hand up to a shoulder use with tilting head for self centering knurls on the workpiece.

To apply for: Form knurling tool for axialaxial and radial feeding up to a shoulder.Radial Feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

Knurl holder “Shoulder-Heavy-Single”

Approved heavy-duty holder for leftand right-hand up to a shoulder use.

To apply for: Form knurling tool for axialaxial and radial feedindg up to a shoulder.Axial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

Knurl holder “Shoulder-Double”

Approved holder with two wheels for left- and right-hand up to a shoulder use.

To apply for: Form knurling tool for axialaxial and radial feeding up to a shoulder.

Axial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

Knurl holder “Shoulder-Single”

Approved holder for left- and righthand up to a shoulder use.

To allpy for: Form knurling tool for axialaxial and radial feeding up to a shoulder.

Axial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

Knurl holder “Self Centering RGE”

Heavy duty holder for right- and left-handed form knurling on rightand left-turning machines. Self centering design.

To apply for: Form knurling tool preferred for axial and radial feed “Diamond” knurling.

Radial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machine types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.

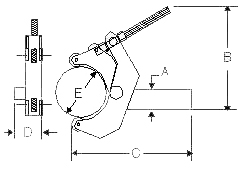

Knurling holder modular

Modular design allows using this holder for single or two die operation. In two die operation a small adjustment allows the head to center itself upon setup. All heads and shanks are interchangeable.

To apply for: Form knurling holder for axialaxial and radial feeding.Radial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machine types: Swiss type, multi-spindle, conventional and CNC lathes.

Cut-knurl holder "RGE"

Approved cut knurling holder with a tilting and scaled head for a better knurl alignment to the workpiece diameter and easy adjustment of the parallelity. Possibility to work on right and left-handed lathes just turning over the head. The modular system allows the use of several different shanks.

To apply for: Cut knurling tool only for axial feeding. The beginning of a knurling in the middle of the workpiece requires a puncture. Knurlings up to a shoulder are not possible.

Axial: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machines types: Multi-spindle, conventional, sliding-head and CNC lathes.

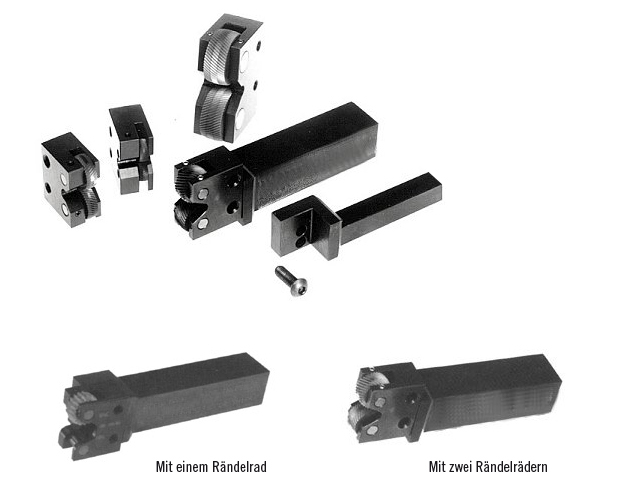

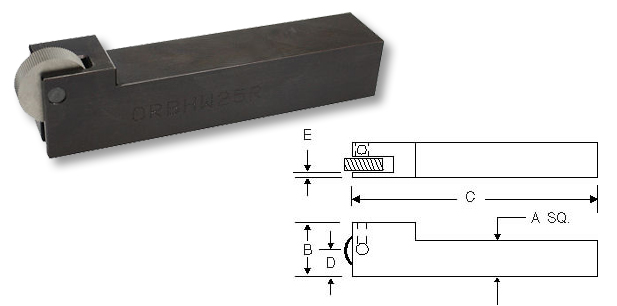

Knurling holder standard

To apply for: Form knurling tool for axialbump knurling and axial feeding

radial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°, GE 30°, GV 30°, GE 45°, GV 45°

axial feed: AA, BR 30°, BL 30°, BR 45°, BL 45°

Machine types: Swiss type, multi-spindle, conventional, sliding-head and CNC lathes.