Rollwalztechnik Abele + Höltich GmbH

Ihr professioneller Partner für die Kaltumformung

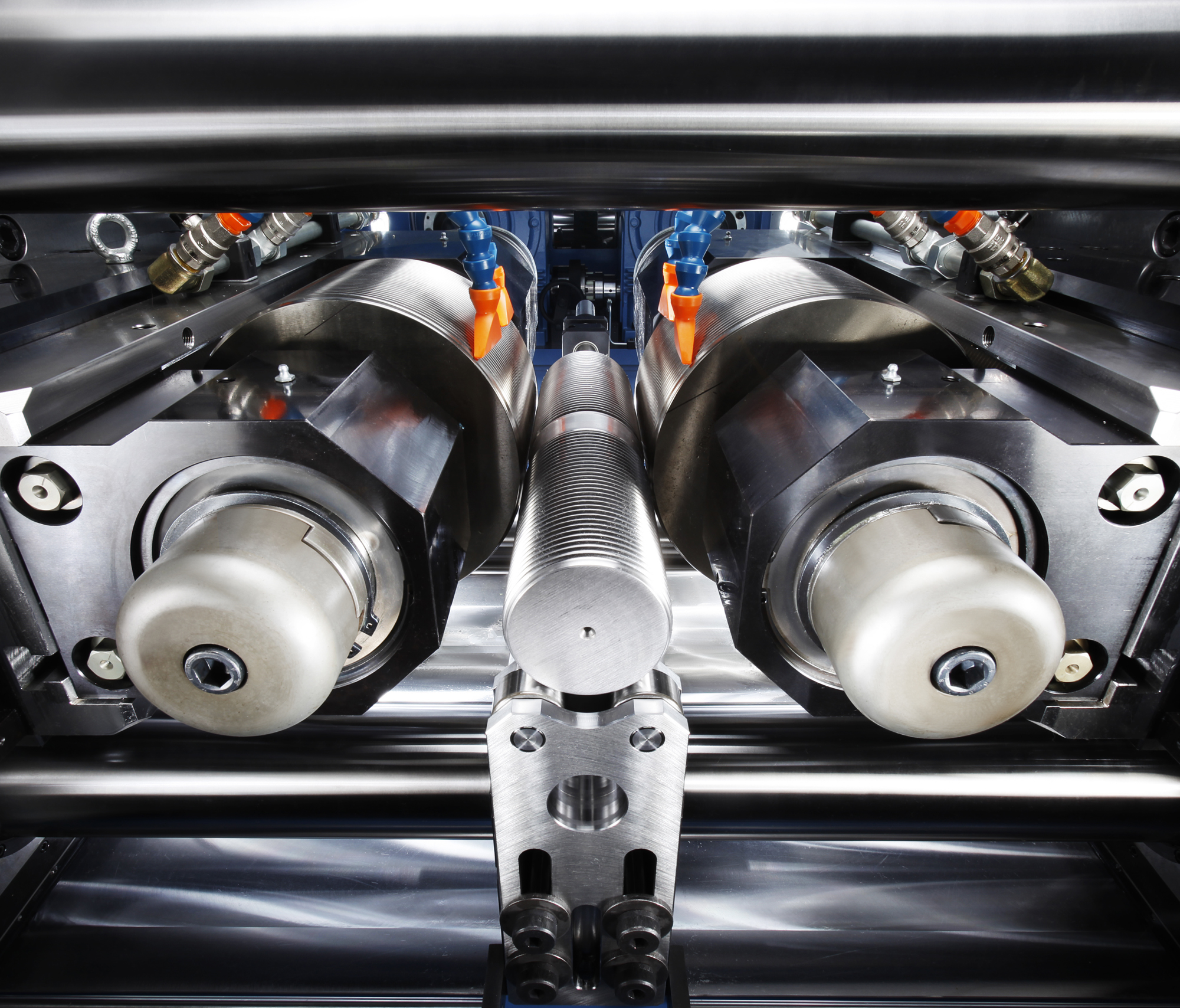

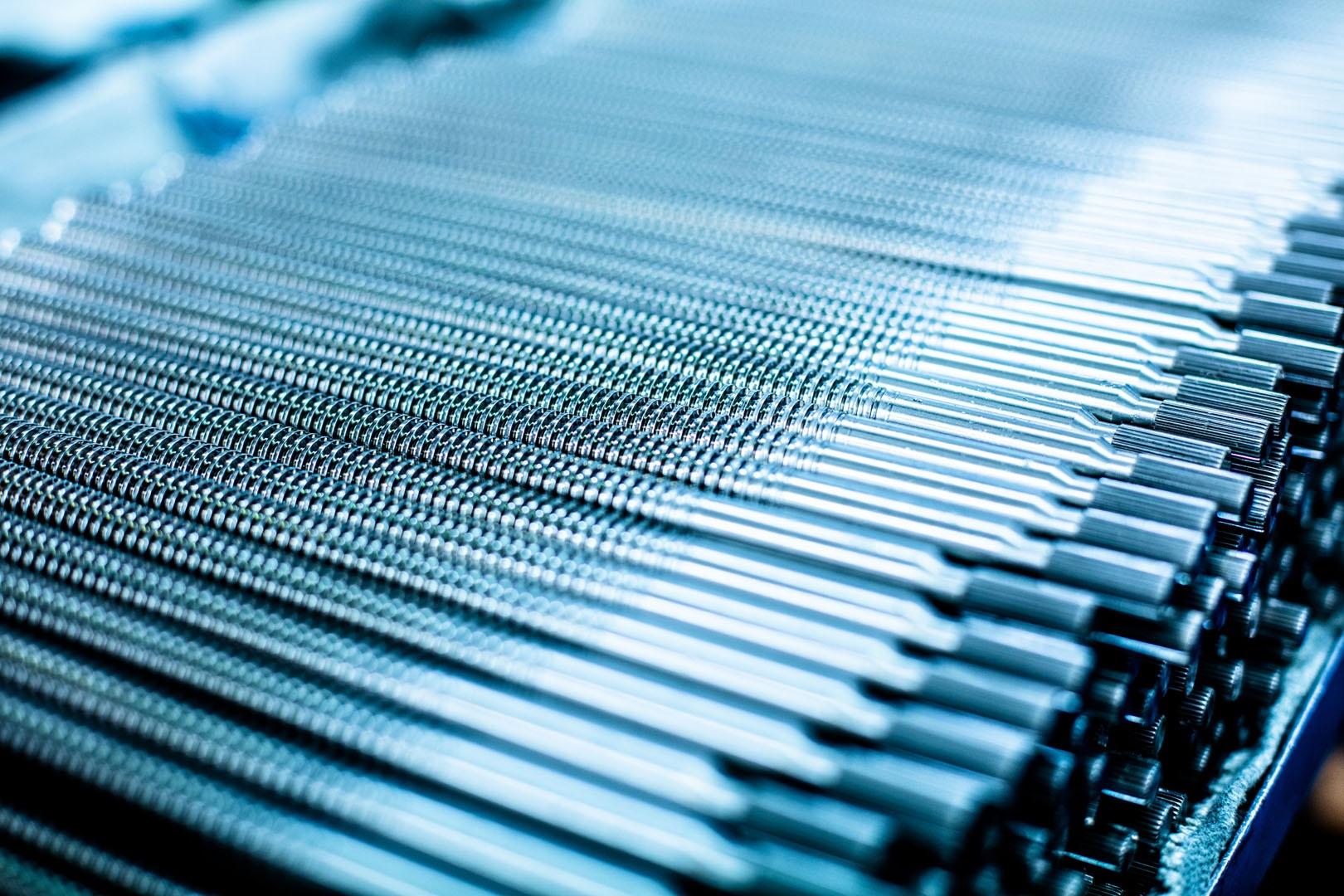

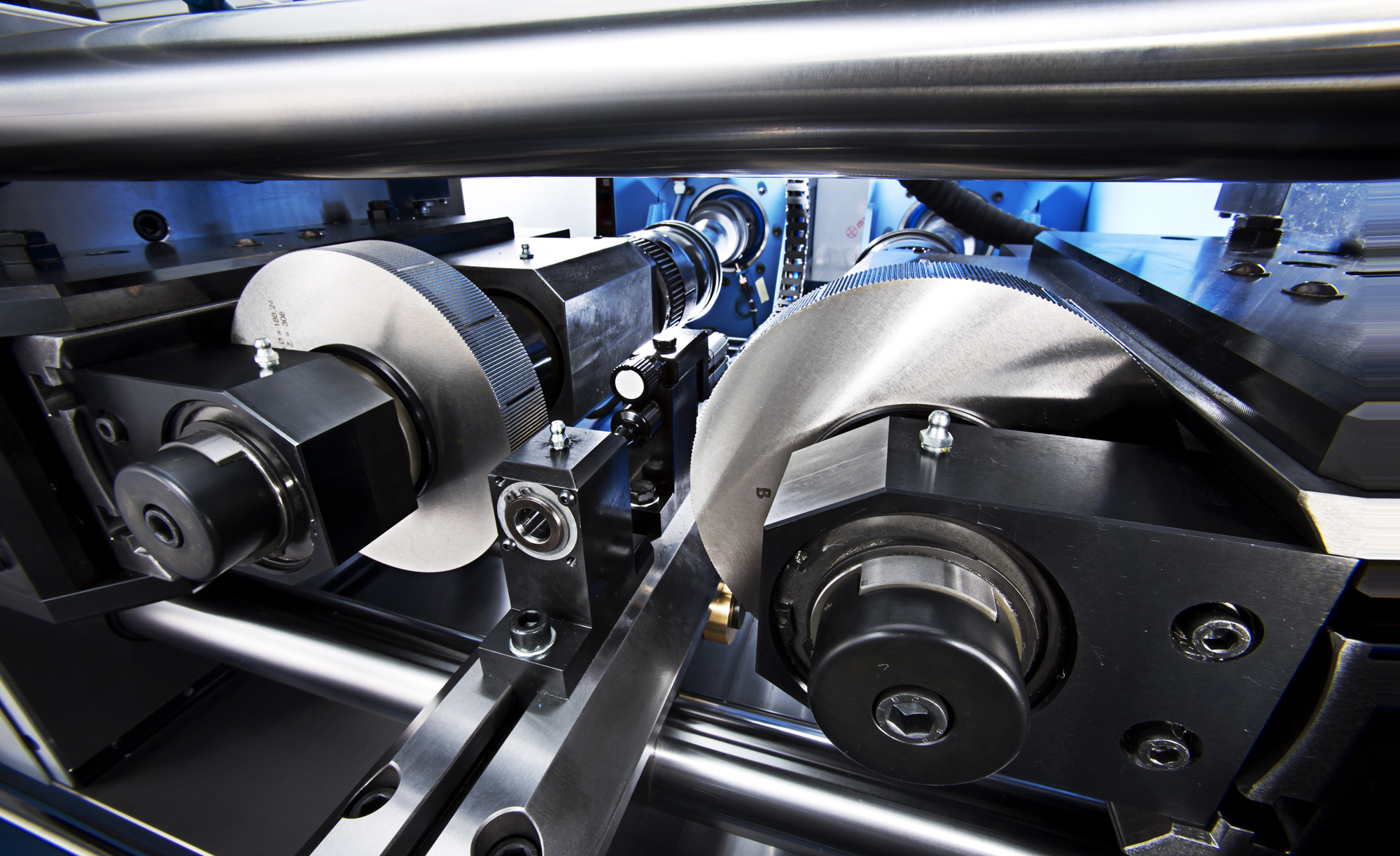

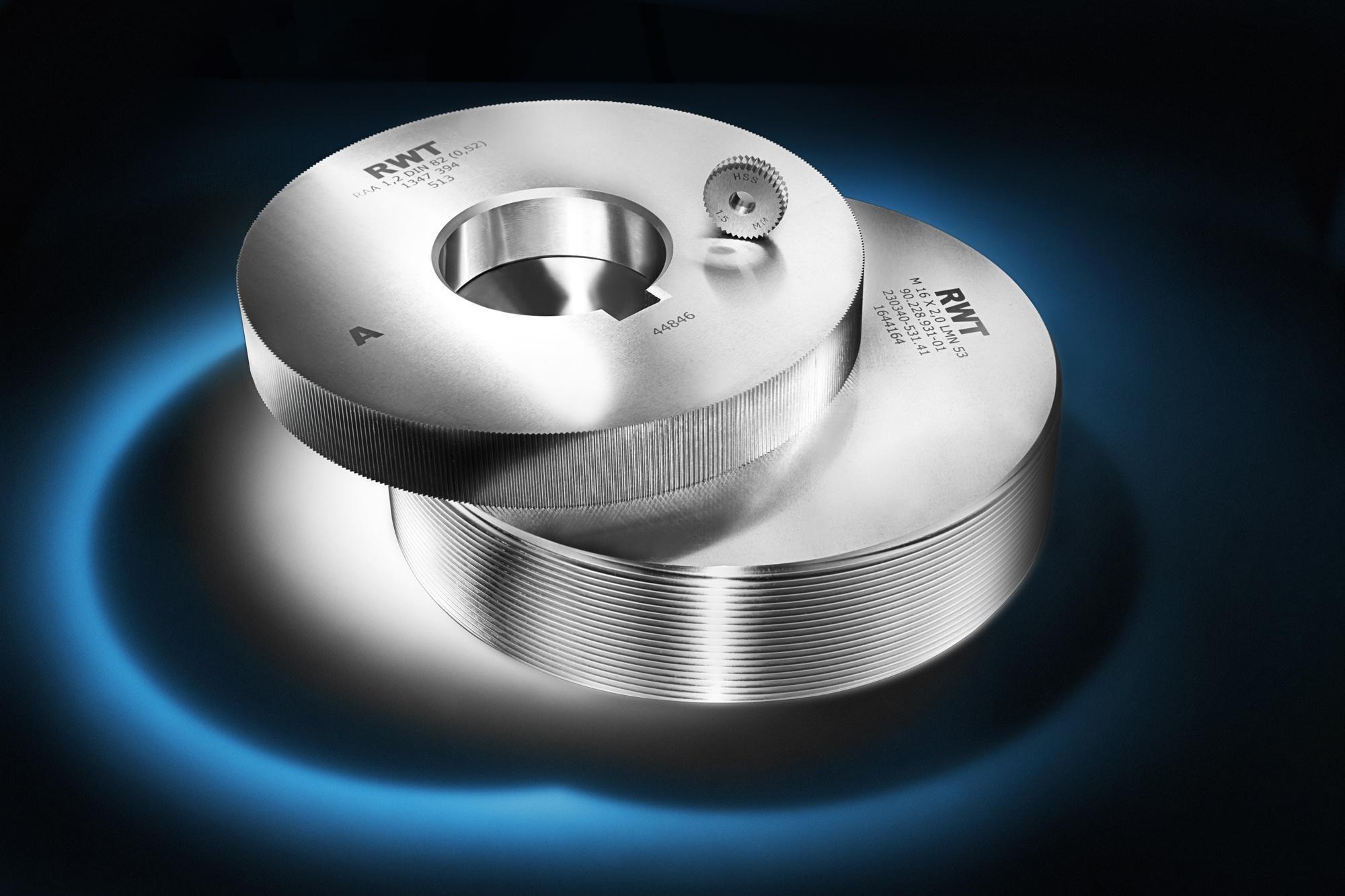

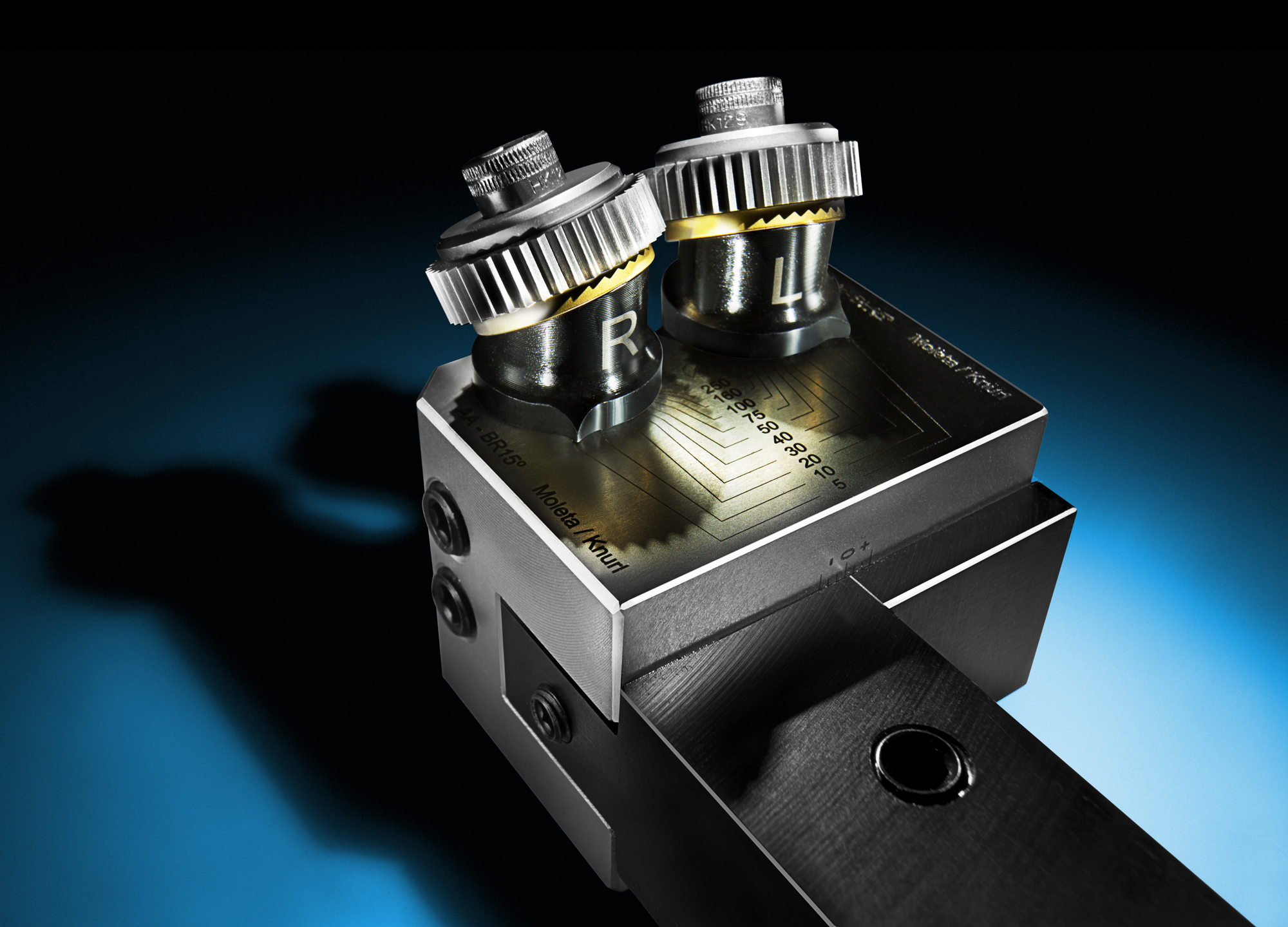

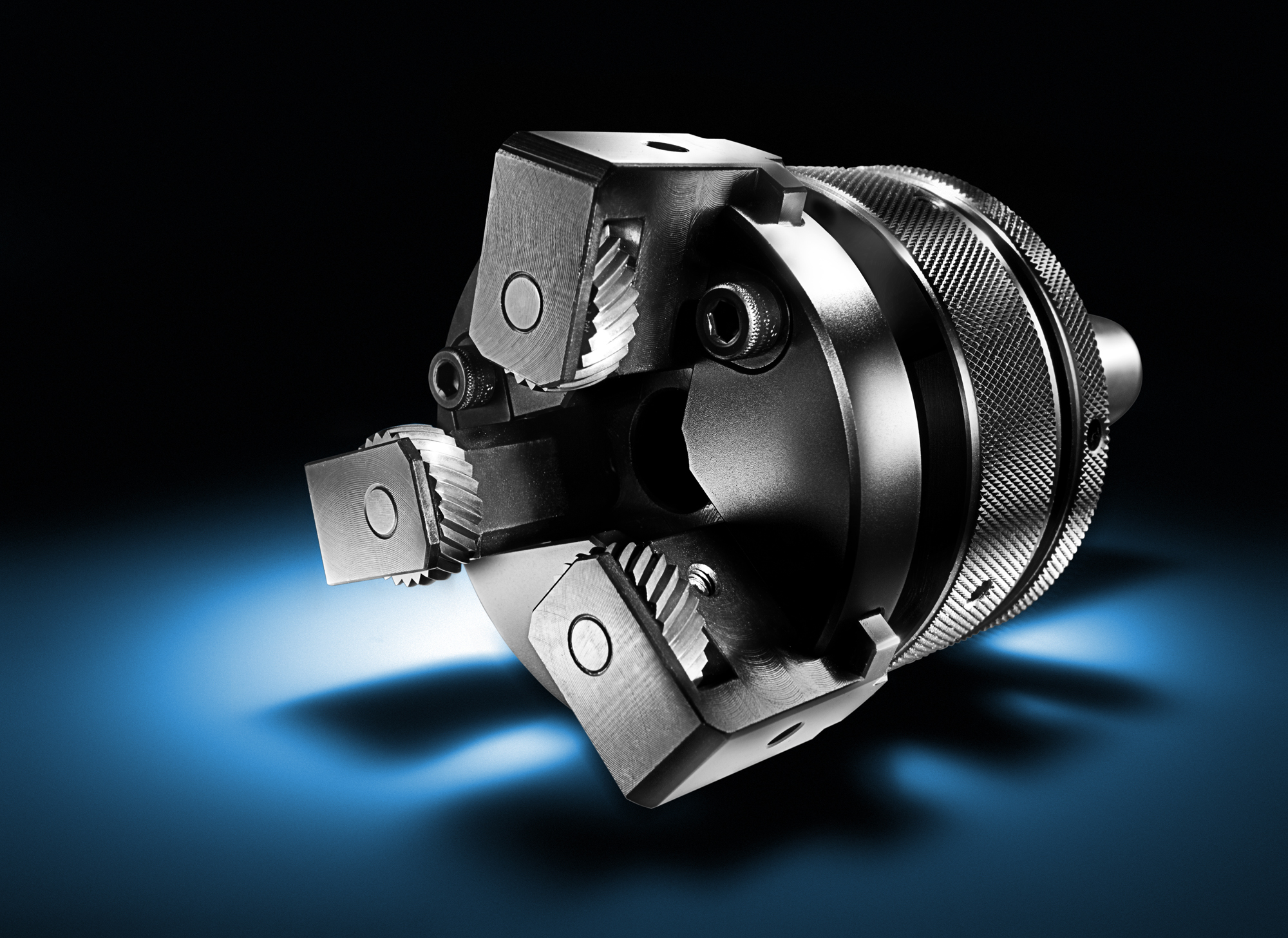

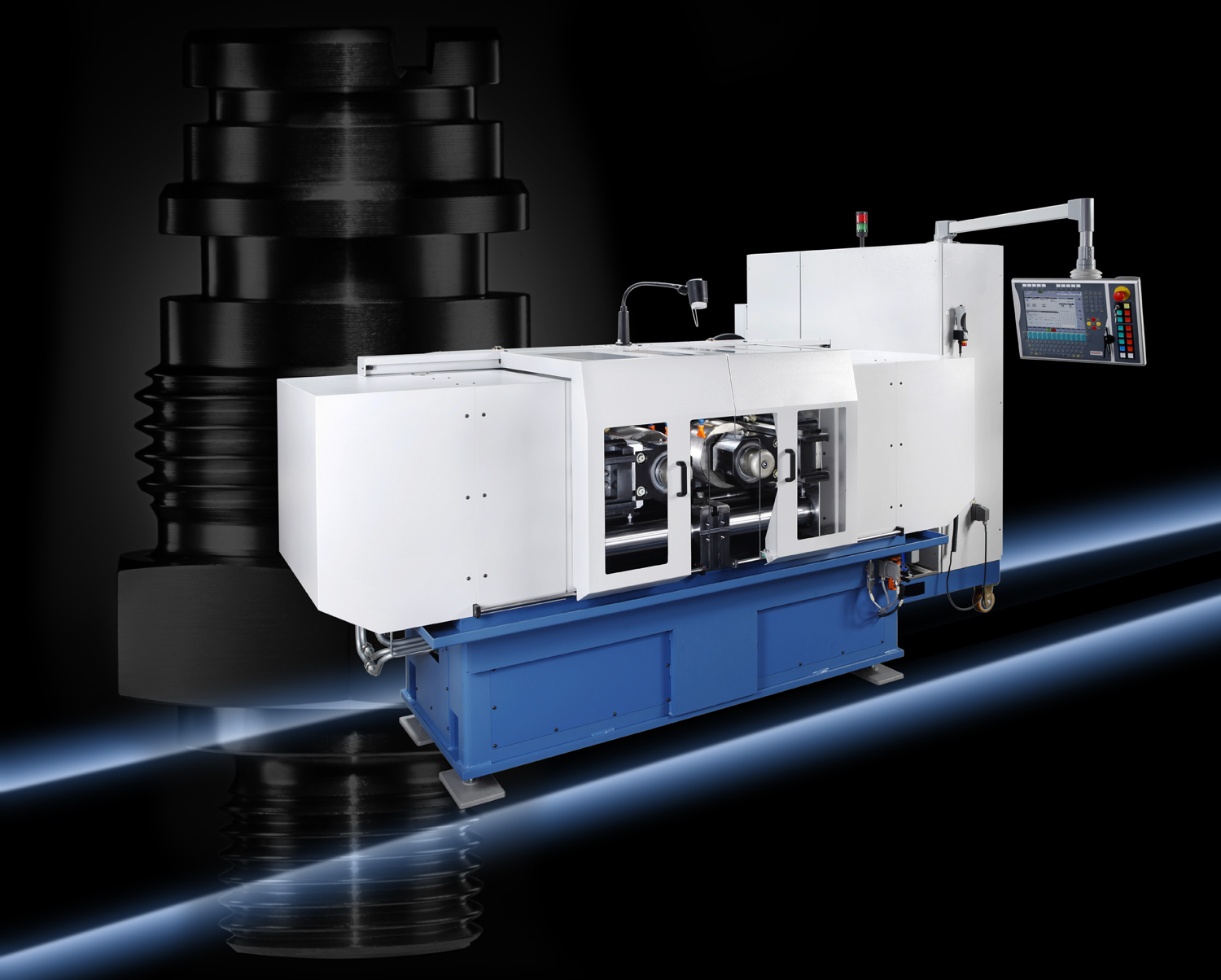

Aus dem Hegau in die ganze Welt: Unser Name steht für hochpräzise Gewindewalzmaschinen, Gewinderollmaschinen, Rändelmaschinen, Profilwalzmaschinen und Verzahnungswalzmaschinen und die entsprechenden Werkzeuge

Seit 1982 konstruieren, produzieren und liefern wir Maschinen und auch Werkzeuge für die noch so individuellsten Anforderungen des Gewindewalzens. Unsere Produkte kommen in den verschiedensten Branchen zum Einsatz: Ob Automotive, Luft- und Raumfahrt, Maschinenbau oder Medizintechnik – nur vier von einigen zukunftsträchtigen Wirtschaftszweigen, die wir zu unseren Kunden zählen dürfen.

Maschinen & Werkzeuge, Projekte

Rollwalztechnik Abele + Höltich GmbH – Maschinen und Werkzeuge

hergestellt für Ihre individuellen Anforderungen.