Machines

Projects

RWT produces and supplies this compact rolling system for integration into production lines.

RWT 30X CNC with bar feeder and disposal

Equipment:

- Workpiece length: 150 - 3000 mm

- Workpiece diameter: 10-20 mm

- Workpiece diameter: 10-20 mm

- Siemens S7 PLC control with remote maintenance

- Coolant filter and cooling unit

- Machine can be moved laterally by motor

RWT 30X CNC/FR for thread rolling of wood screws

Equipment:

- processing device for wood screws up to 2000 mm in length

- Coolant cooling and filtering unit

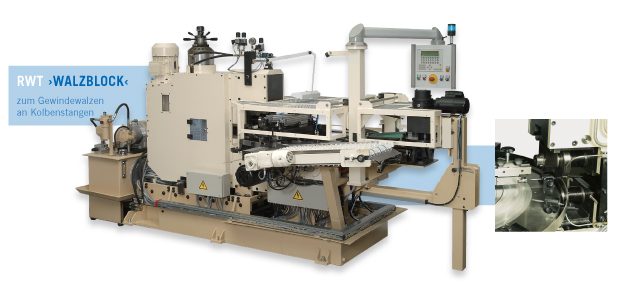

RWT 20X CNC for knurling of motor shafts

Equipment:

- Timed belt feeder End rolling device

- Lifting level for workpiece feeding into the end rolling device

- Lifting level for automatic measuring of the blanks

- CNC rolling control with automatic program selection, depending on the blank diameter measured

- Hydrodynamic compensation for slackness

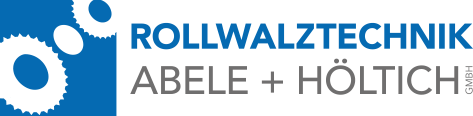

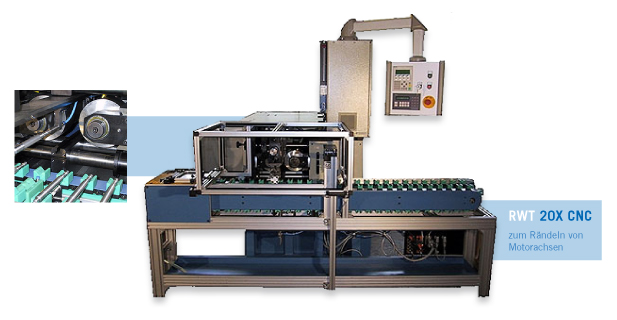

RWT "Walzblock" for thread rolling on piston rods

Equipment:

- 12 position switch plate

- Part lengths variable 150 - 380 mm

- 46 parts per minute

- The parts are picked up from a continuous conveyor belt, processed and fed back to the conveyor belt

- Inverting wheel

- Minimum quantity lubrication

MDS hydraulic for knurling of windshield wiper motor axes

Equipment:

- RAA 1 and 1.2 DIN 82

- Feeding by means of a step feeder and linear insertion

- 15 pieces/min

- Rolling force 8t

- Drive power 4 kW

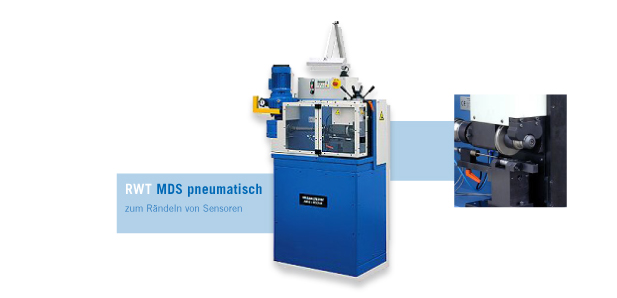

MDS pneumatic for knurling of sensors

Equipment:

- Hydr. CNC axis

- Automatic workpiece recognition

- Safety curtain

- Rolling force monitoring

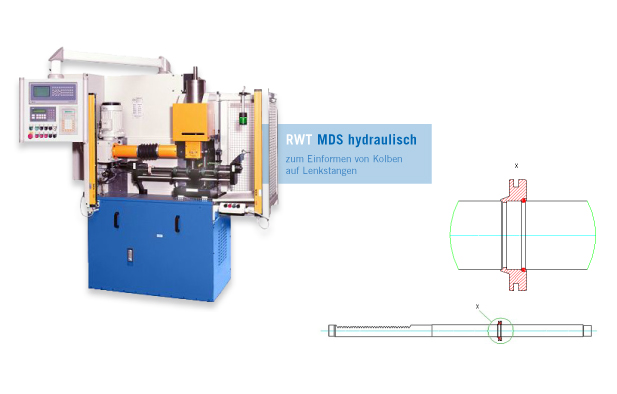

MDS hydraulic for fixing pistons on steering rods

Equipment:

- Hydr. CNC axis

- Automatic workpiece recognition

- Safety curtain

- Rolling force monitoring